DIY Custom Wooden Chessboard: A Game Piece That Stands Out

Crafting Your Own Heirloom-Quality Wooden Chessboard at Home

Jul 25, 2024 - 16:13 • 5 min read

Introduction

There's something timeless and captivating about a beautifully crafted wooden chessboard. Not only is it a fantastic piece for game lovers, but it also serves as a stunning decorative item for your living space. In this DIY guide, we will take you through the journey of creating your own custom wooden chessboard. The process is detailed, yet immensely rewarding, providing you with an heirloom-quality piece that you can cherish for generations.

Why A Custom Chessboard?

A custom chessboard allows you to personalize the materials, design, and craftsmanship to suit your taste, ensuring it reflects your style and preferences. It's a wonderful way to invest time in a creative project while also producing something functional and beautiful. Whether you’re new to woodworking or an experienced artisan, this project offers something for everyone.

Materials and Tools You'll Need

Before diving into the construction process, let's gather all the necessary materials and tools. Trust us, being prepared will make your project go much more smoothly.

Materials

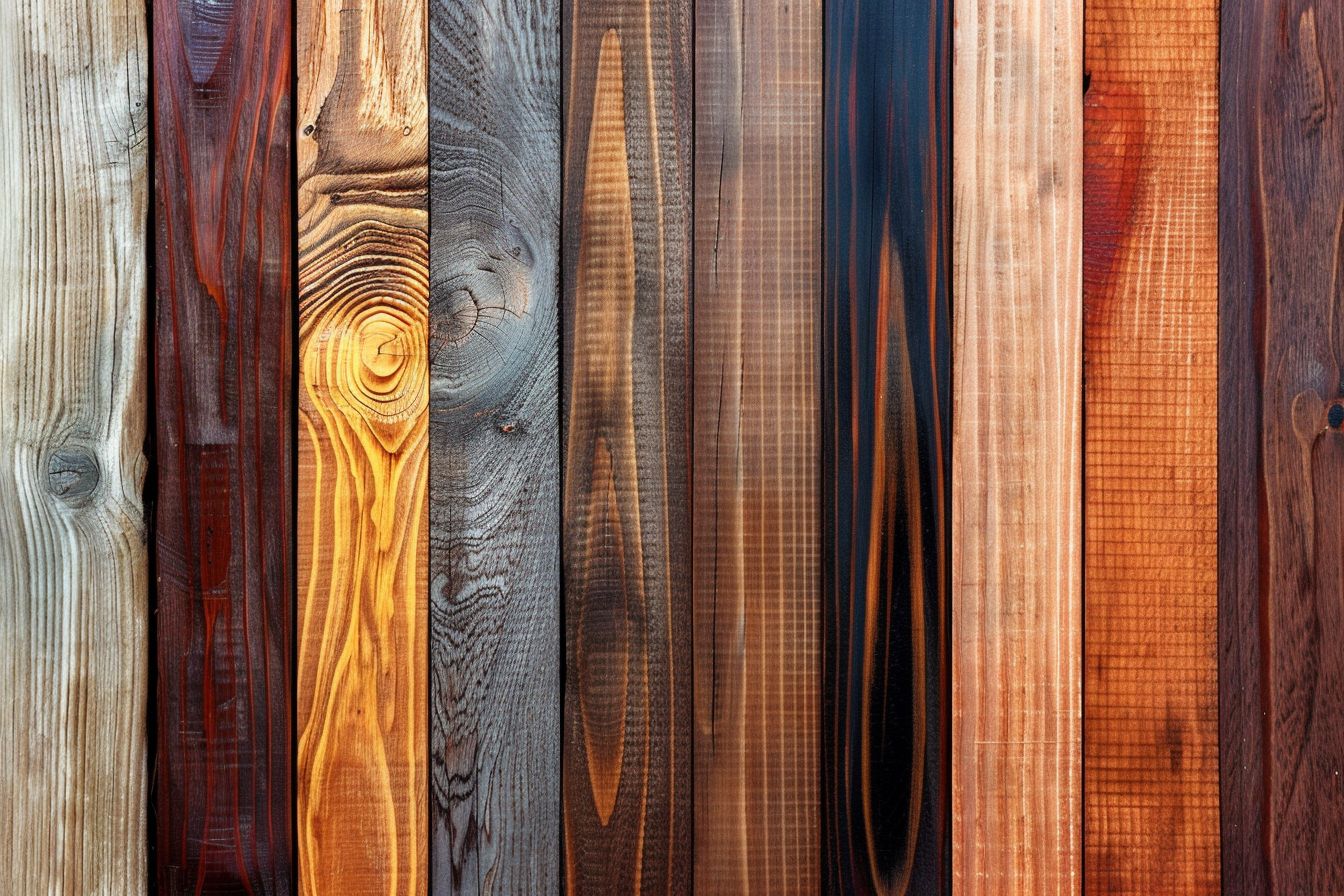

- Two different types of wood (one light, one dark) for the playing squares (e.g., maple and walnut)

- Plywood sheet for the base

- Wood glue

- Clamps

- Sandpaper (variety of grits)

- Wood finish or polyurethane

- Paint or wood stain (optional for border)

Tools

- Table saw or miter saw

- Router and router bits

- Wood planer (optional but recommended)

- Measuring tape

- Pencil

- Straightedge

- Safety equipment (gloves, goggles, ear protection)

Step-by-Step Guide to Building Your Chessboard

Step 1: Preparing the Wood

Start by selecting two contrasting types of hardwood for your chessboard squares. Cut these into strips that are the same width. For a standard 8x8 chessboard, you will need 32 squares of each wood type.

- Thickness Planning: If your wood isn't already the same thickness, use a planer to make sure each piece is uniform. This will ensure your chessboard is level and looks professional.

- Straightening Edges: Use a table saw to rip the strips to the desired width.

Step 2: Cutting the Squares

Now cut the strips into squares. Each square should be the same size.

- Measuring: Measure the width of your strips and set your saw to cut them into the same length, creating perfect squares.

- Cutting: Cut 32 squares from each of the two wood types.

Step 3: Assembling the Board

Arrange your squares in an 8x8 grid pattern, alternating the wood types to form the classic chessboard look. Glue the squares together row by row, and then glue the rows together.

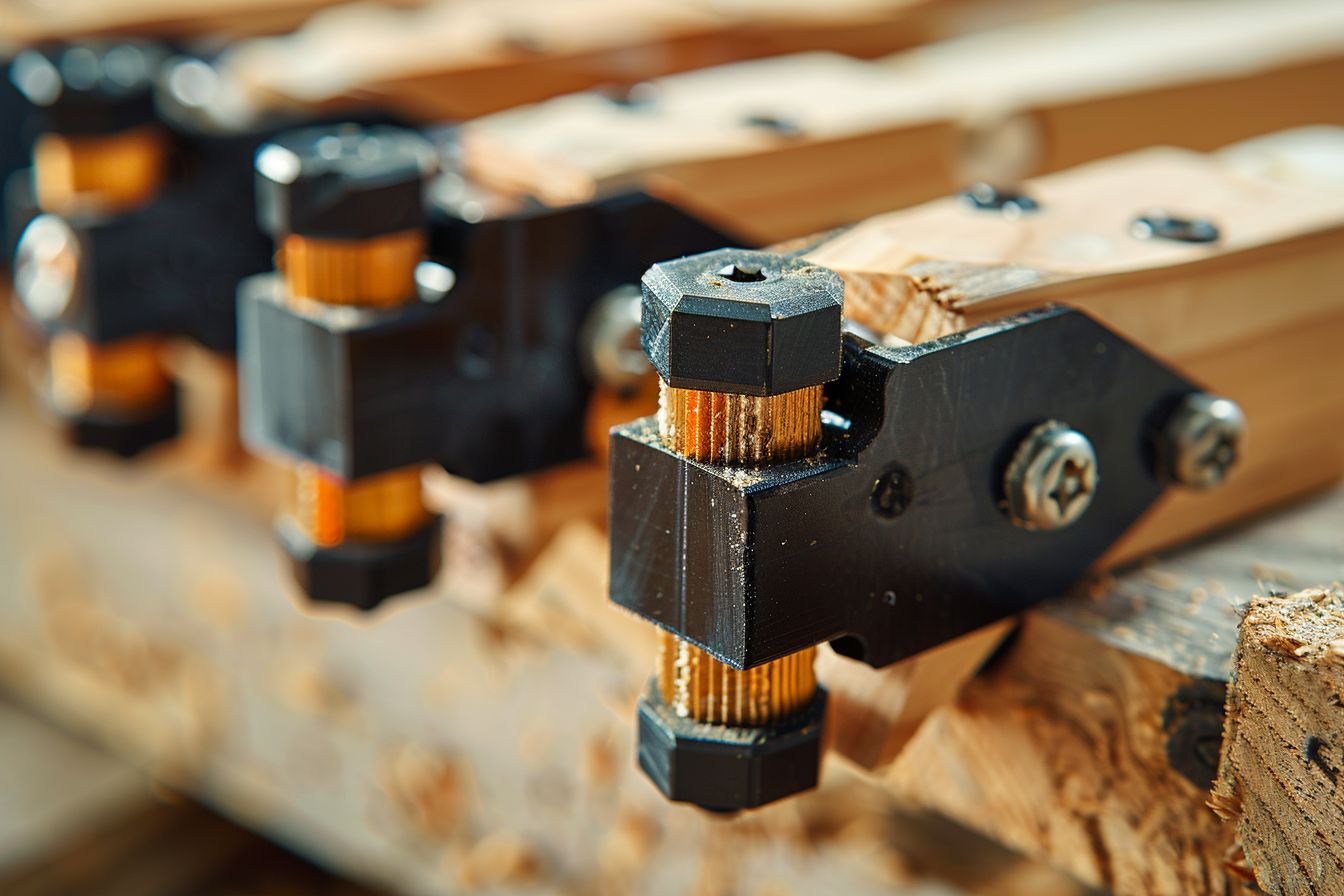

- Gluing: Apply wood glue to each edge and clamp the squares together. Let the glue dry thoroughly.

- Clamping: Use clamps to hold everything tightly in place as the glue dries. Check for any misalignment and adjust as needed.

Step 4: Adding the Border

For a polished look, add a border around the chessboard. Cut strips of wood for the border and miter the corners for a clean fit.

- Cutting the Border: Measure and cut the border pieces to fit around the chessboard.

- Attaching the Border: Glue and clamp the border pieces to the chessboard.

Step 5: Sanding and Finishing

Sanding is crucial for a smooth, professional finish. Start with a coarse grit and work your way to a finer grit.

- Sanding: Sand the entire chessboard, including the border, until smooth.

- Finishing: Apply a wood finish or polyurethane to protect the wood and give it a glossy appearance. Let it dry completely before use.

Insights and Practical Tips

- Wood Choice: Experiment with different types of wood to find combinations that you love. Common pairs include maple and walnut, cherry and oak, or birch and mahogany.

- Precision: Take your time to ensure each cut is as precise as possible. This will save you trouble during assembly.

- Safety: Always wear proper safety equipment when working with power tools.

Challenges and Solutions

Common Challenges

- Misaligned Squares: This can result from uneven sanding or imperfect cuts. Use a straightedge while assembling to ensure alignment.

- Gluing Issues: Sometimes, glue can squeeze out between the squares. Wipe off excess glue immediately and ensure even clamping pressure.

- Uneven Surface: Sanding patiently is key. Start with a coarse grit and gradually move to finer grits for a smooth finish.

Solutions

- Pre-Planning: Double-check measurements and dry-fit pieces before gluing.

- Proper Clamping: Invest in quality clamps to ensure even pressure and avoid misalignment.

Future Trends and Innovations

DIY woodworking has seen significant advancements with technologies like CNC machines and laser cutters. These machines offer extreme precision and can create intricate designs that are hard to achieve manually.

Additionally, there is a movement towards sustainable woodworking. Using reclaimed or locally sourced wood can add a unique story to your pieces and contribute to environmental conservation.

Conclusion

Crafting your own custom wooden chessboard is a rewarding project that results in a beautiful and functional piece. It combines creativity with skill, offering you a chance to create something truly unique. We hope this guide inspires you to embark on this fulfilling DIY journey. Remember, patience and precision are key to achieving the best results. Enjoy the process and happy crafting!

For any decisions based on the content provided, always seek professional advice.